Blog

Automation in Luxury Gift Box Production: Precision, Efficiency & Sustainability

The Industry Challenge

- Manual craftsmanship alone can no longer meet modern demands

- 48-hour production delays due to hand-assembly bottlenecks

- Structural limitations in complex designs (e.g., multi-layer drawers, magnetic closures)

- 30% annual labor cost inflation impacting pricing competitiveness

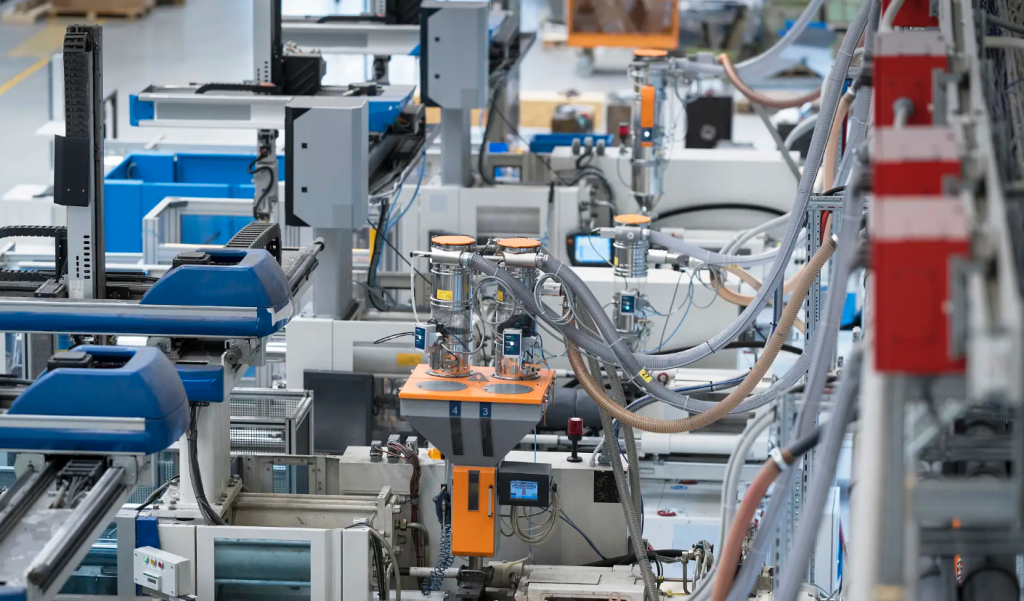

Our Technology-Driven Solutions

1.AI-Enhanced Digital Cutting Systems

- Hybrid laser/steel-rule die cutting achieves ±0.2mm tolerance (vs. industry standard 1mm)

- Case Study: 15,000-unit luxury perfume box order with debossed leather textures delivered in 72 hours

2. Robotic Lamination Lines

- Automatic foil stamping & specialty material bonding (wood veneer, silk fabrics)

- Zero-bubble guarantee: Infrared drying tunnels eliminate adhesive imperfections

3. Agile Production Cells

- Changeover within 15 minutes via modular tooling

- Economical MOQ of 150 units for limited-edition collections

Data Spotlight:

Automation reduced lead times by 40% while increasing structural accuracy by 68% (2024 internal audit)